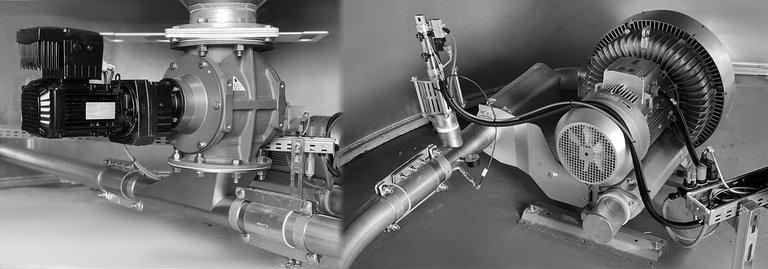

Our rotary valves are used for metering plastic granules in material lines. The geared motors are all equipped with a frequency converter for pressure-controlled conveyance. A bulk material deflector is installed at the inlet of the rotary valve, which prevents damage to the plastic granules due to shearing between the rotary valve and the housing.

For the discharge of leakage air we offer a leakage air collector. The leakage air connections on the rotary valves are prepared and sealed with a blind plug. For the connection between the rotary valve and the material line, we supply suitable pipe adapters with various pipe cross sections. These are flow-optimised and optimally guide the granules into the material line.